Football is a high octane, high-impact sport that runs the constant risk of head injuries for participants, particularly concussions and traumatic brain injuries. As our understanding of brain trauma continues to deepen, so does the undeniable need for more sophisticated football helmet testing methods. While traditional impact tests have help set existing standards, recent technological advancements have helped push helmet safety to new heights.

From AI-driven simulations to bioengineered materials, the future of helmet testing is evolving to provide maximum protection for athletes. Below, we’ll explore the latest cutting-edge testing technologies and the future for football helmet safety. Read on to learn more!

The Need for Advanced Helmet Testing

Football helmets have played a crucial role in reducing head injuries at both the amatuer and professional level, but one remaining point of concern is the prevalence of concussions and ongoing risk of long-term brain injuries.While early testing methods focused primarily on direct linear impacts (head on collisions), research now shows that rotational forces also contribute significantly to brain trauma. As we continue to push forward with evaluation methods, Organizations like NOCSAE (National Operating Committee on Standards for Athletic Equipment) and the NFL have begun to revise safety standards to incorporate more comprehensive testing protocols that protect player safety and demand better performance from protective equipment.

In 2025, the message has become clear: Simply meeting baseline safety standards is no longer enough—manufacturers and researchers are looking for ways to enhance helmet design and performance using state-of-the-art technologies.

Advanced Football Helmet Testing Methods

What do advanced testing methods look like for football helmets? There’s a broad gambit of tests for protective gear intended for sports use, including:

Impact Simulation & Drop Tests

Modern helmet testing relies on high-speed impact simulations to measure how well helmets absorb force. Advanced drop test rigs and sensor-equipped dummy heads help scientists and engineers replicate real-world collisions and assess a helmet’s ability to dissipate energy effectively.

Linear vs. Rotational Impact Testing

Rotational forces—which cause the brain to twist inside the skull—are now recognized as a major factor in concussions. Emergent helmet testing methods are designed to measure both linear and rotational accelerations, offering a more complete understanding of how helmets protect players and paving a better path forward for future designs.

Smart Helmet and Mouth Guard Technologies

Smart helmets, and now smart mouth guards, have been a game changer for the safety industry, with embedded senors providing real-time data on the severity and frequency of head impacts, allowing coaches and medical professionals to monitor a player’s exposure to potential brain injuries. This empowers players and their coaching staff to stay safe utilizing both a reactive and proactive approach.

The Future of Football Helmet Testing

The evolution of football helmet testing remains a top priority in 2025 and beyond. With technology bridging knowledge gaps on a routine basis, researchers now have more tools than ever before to help understand real risks to players, and provide real results that effect change. Key technology and developments to keep an eye on include:

AI & Machine Learning in Helmet Safety

Artificial intelligence (AI) and machine learning are used to analyze thousands of impact scenarios, identifying patterns that help engineers design safer helmets. AI-driven simulations are being used to help efficiently predict how different helmet materials and designs will perform under various conditions, accelerating the research and development and often reducing the overall repetitive load on researchers.

3D Printing & Custom Helmet Design

3D printing has opened the door for custom-fit football helmets that offer a promising concept for safety. Using a player’s head scan, manufacturers can create helmets with an exact fit, improving both comfort and protection by reducing unwanted movement inside the helmet, which minimizes the risk of concussions caused by rotational forces. Greater levels of customization and safety could be reached by leveraging Additive Manufacturing or 3D printing technologies that potentially offer greater levels of impact performance at each region of the helmet without many of the traditional manufacturing and design restrictions thereby offering greater design flexibility in terms of performance, comfort, fit and heat dissipation.

Bioengineered Materials for Enhanced Safety

Researchers are exploring next-generation materials that have been shown to absorb and disperse impact forces more efficiently than traditional foams. Nanotechnology-infused padding, flexible polymers, and energy-absorbing gels are being integrated into helmet designs to offer superior protection. Best of all, these materials not only enhance safety but also improve durability, making helmets last longer without compromising performance.

Leading the Charge in Helmet Testing with Biokinetics

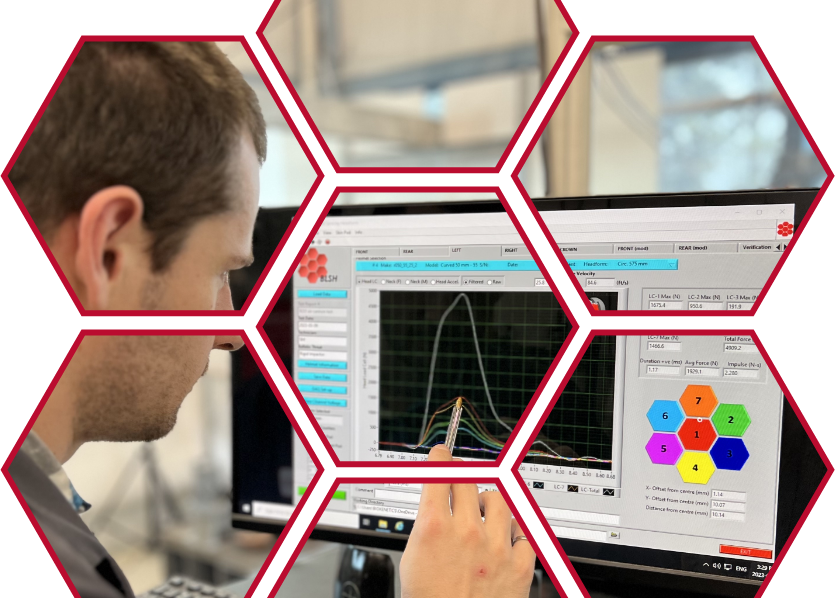

At Biokinetics, we’re passionate about staying at the forefront of safety practices, and are proud to offer almost 50 years of leading experience when it comes to innovative helmet testing and more. Based in Ottawa, Canada, our work has helped manufacturers comply with safety standards, and help inform industry decisions about the validity of emerging testing protocols and premises.

From advanced drop test systems to replicate rotational forces, Biokinetics remains committed to pushing safety standards forward both in the lab and in the public discourse.

Learn more about helmet design expertise and our helmet testing services by contacting our team today.