Ballistic testing is a critical process that ensures the development of protective gear that can withstand the dynamic and unyielding demands of military personnel, law enforcement personnel, and other high-risk industries.

The ability to withstand high-velocity projectiles and impact forces is often a matter of life or death for individuals wearing body armour. Continuous advancements in ballistic testing equipment and protocols have significantly improved the accuracy and reliability of protective equipment, increasing their overall safety and effectiveness. As modern understandings of risk continue to evolve, industry leaders like Biokinetics continue to refine testing efforts to gather the most effective data possible for harm mitigation.

Below, we’ll explore the science behind ballistic testing, including the key components of modern testing equipment and how companies like Biokinetics are helping set new standards for safety and performance. Read on to learn more!

Defining Ballistic Testing?

Ballistic testing is the process of evaluating the ability of materials and protective gear to withstand the impact of projectiles such as bullets, shrapnel, and other high-velocity objects. The ultimate goal of such tests is to measure how well a material absorbs and disperses kinetic energy, lowering the chances of lethality. Ballistic testing is crucial for a wide range of applications, including:

- Military and Law Enforcement

- Sports

- Automotive and Aerospace, and more.

Ballistic testing involves firing a projectile at a test sample under controlled circumstances designed to replicate real-world conditions. The results of each test are then analyzed to determine how much energy was absorbed, whether the material was penetrated, and the extent of backface deformation (denting or bulging). Understanding these variables helps ensure that equipment is prepared to function properly during actual use.

Key Components of Modern Ballistic Testing Equipment

Fueled by technological advancements, modern ballistic testing equipment allows for a higher level of precision, data collection, and reliable results. Present-day setups also allow for more specialized tools and systems to be applied to capture detailed data about impact forces and material performance. Such technology includes:

1. High-Speed Cameras

When fired, projectiles move at an extreme rate of speed; high-speed cameras are essential and allow tests to capture thousands of frames per second, providing detailed visual data on how they behave upon impact. Behaviours of note may include fragmentation patterns, material deformation, and more. Such data allows researchers to study the dynamics of an impact in detail and adjust the material design accordingly.

2. Pressure and Force Sensors

Pressure and force sensors measure the energy transferred from a projectile to the target material, which helps to relay how well materials absorb and disperse energy for optimal performance and protection. Accurate pressure data ensures that the material meets performance benchmarks under real-world conditions and helps to improve upon designs over time.

3. Environmental Chambers

Protective gear is subject to various environmental conditions that complicate performance and increase risk. Ballistic testing must also factor in different temperatures, humidity levels, and atmospheric conditions to ensure that materials remain effective even under extreme conditions.

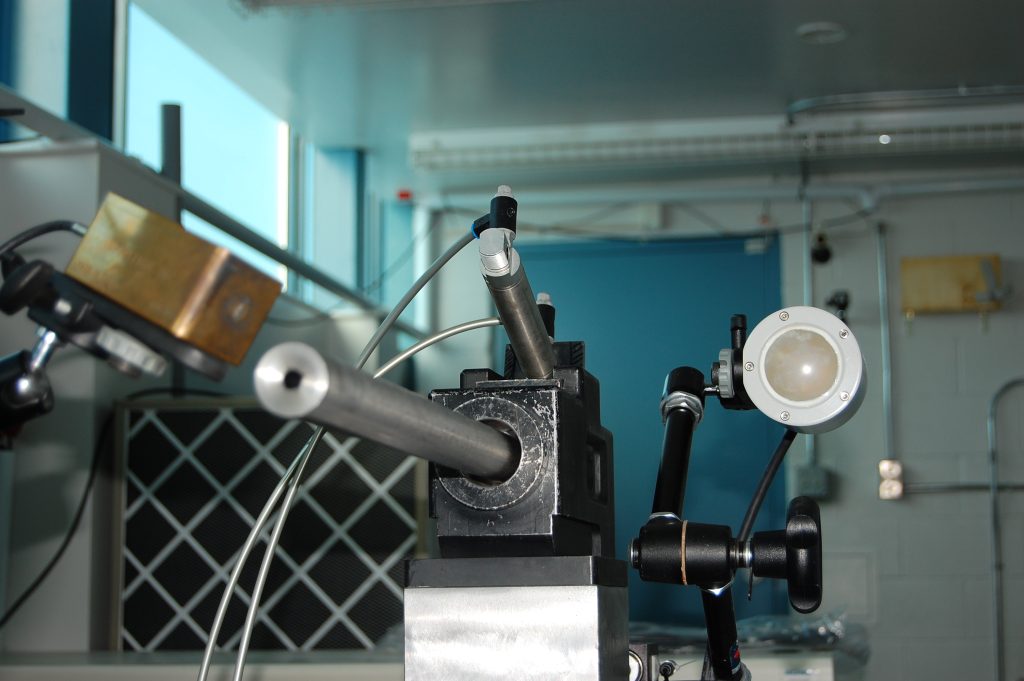

4. Universal Receivers

In ballistic testing, a universal receiver is a specialized, highly precise, and modular testing device used to fire a variety of ammunition types under controlled conditions. Unlike standard firearms, which are designed for practical use in the field, universal receivers are built to provide repeatable, consistent testing environments for ammunition manufacturers, forensic analysts, and military research.

Using modern equipment results in better, more reliable data, precise points of resolution, and a faster time to market for manufacturers.

Industry Standards and Compliance

Protective gear is subject to strict safety standards that help to ensure uniform performance and reliability in the field. Ballistic testing is key to helping manufacturers align with widely recognized standards like:

- NIJ (National Institute of Justice): Sets standards for ballistic-resistant body armour used by law enforcement.

- ASTM (American Society for Testing and Materials): Provides guidelines for testing materials and protective gear.

- ISO (International Organization for Standardization): Establishes international safety and performance standards for protective materials.

Meeting these standards requires highly accurate and repeatable test data acquired through ballistic testing in controlled settings. Manufacturers rely on detailed data from testing systems to adjust designs, improve performance, and demonstrate compliance with these rigorous benchmarks.

Biokinetics’ Role in Advancing Ballistic Testing

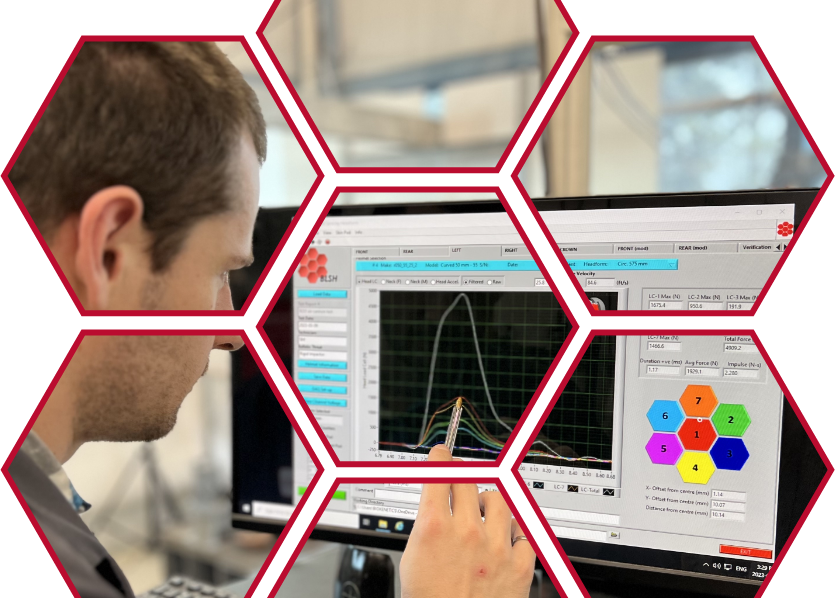

Biokinetics has been a leader in injury prevention and protective gear testing for nearly 50 years. With experience that spans the design, development, and testing of protective equipment for military, law enforcement, and sports applications, our testing facilities are equipped with state-of-the-art equipment, including high-speed imaging systems, precision force sensors, and automated targeting systems. This allows our engineers to provide highly detailed and accurate test data you can trust and even develop custom testing protocols based on unique operational requirements.

Learn more about our ballistic testing and related services by contacting us today!