Wearing a helmet is one of the most important ways to protect ourselves from serious injury. Whether being used while playing recreational sports, on an industrial job site, or in high-risk fields like military and law enforcement sectors.

Helmet testing helps ensure protective equipment performs as intended when it matters most and helps to evaluate each unit’s performance, durability, and effectiveness against impact forces.

At Biokinetics, we know advanced testing solutions help manufacturers develop and certify helmets that meet and exceed stringent safety standards. With decades of experience behind our team, we’re proud to support safe performance and the evolution of current standards with data you can trust. Read on to learn more about the importance of helmet testing.

Why Helmet Testing is Essential

A helmet’s primary function is to absorb and dissipate impact energy during a sudden collision or fall. The kinetic energy that occurs in such instances can put us at risk for serious injuries, such as traumatic brain injuries (TBIs) and skull fractures. While effective helmets can help to offset this risk, improper designs or substandard materials can lead to insufficient protection.Helmet testing is therefore intended to assess key performance factors like:

- Impact absorption

- Penetration resistance

- Blunt trauma protection

- Environmental durability

- Rotational force mitigation (an increasing focus at present)

With the right testing protocols, manufacturers can refine helmet designs and materials to optimize safety without compromising comfort or usability.

Types of Helmet Testing Equipment

Helmet testing requires sophisticated tools and technologies, alongside operational expertise, to measure impact response accurately. Below are common types of equipment used in modern helmet testing facilities:

1. Drop Towers for Impact Testing

Drop towers are some of the most widely used helmet-testing devices. As the name suggests, helmets are mounted on head forms and dropped from controlled heights onto solid surfaces to simulate real-world impact scenarios.

Sensors within the head model measure acceleration forces, helping manufacturers determine whether a helmet can effectively disperse impact energy. Drop tests are crucial for simulation and help create repeatable, standardized test conditions.

2. Penetration and Ballistic Testing Systems

Helmets used in military and law enforcement applications must test for penetration resistance to help protect operators against high-velocity projectiles like shrapnel, bullets, and stabbing threats. Advanced ballistic testing systems help ensure compliance with global protective gear standards and ensure that helmet materials stand up to extreme forces encountered in combat scenarios.

3. Blunt Impact and Rotational Testing

Blunt trauma testing focuses on how well a helmet protects against concussive forces. This can help reduce the risk of TBIs, identify weak points, and provide design teams with valuable feedback to help iterative designs and safety improvement for future models.

4. Environmental and Durability Testing

Finally, helmets must be able to perform reliably, even in diverse conditions. Environmental testing chambers are key to determining how a unit functions in extreme temperatures, under UV exposure and how it holds up against humidity to assess long-term durability. Compression tests also determine whether helmets maintain their protective capabilities after prolonged use.

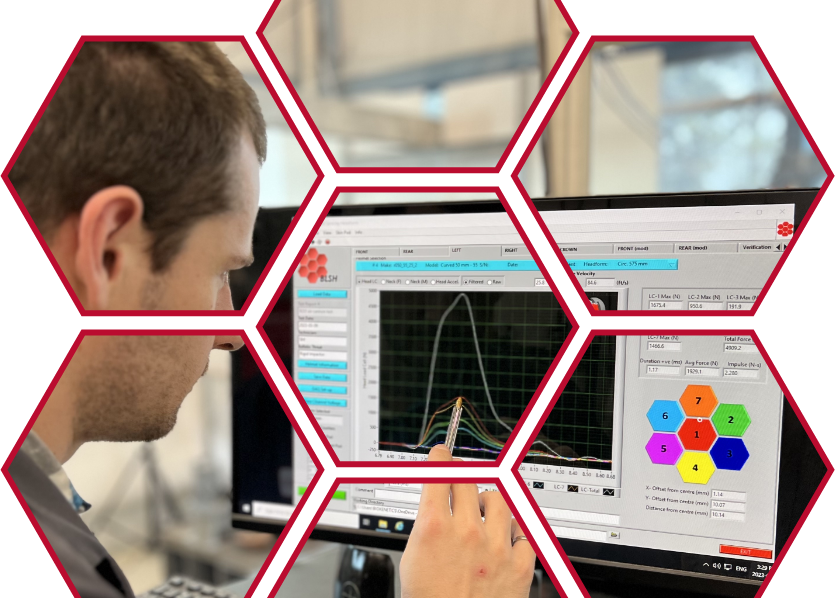

Biokinetics: Advancing Helmet Testing Technology

With nearly five decades of expertise in protective equipment testing, Biokinetics is proud to remain at the forefront of helmet safety research and evaluation. By leveraging state-of-the-art testing methodologies and facilities, Biokinetics provides precise data that allows manufacturers to refine helmet designs and enhance overall performance.

Our advanced testing solutions help industries develop helmets that meet international safety regulations, including:

- NIJ (National Institute of Justice) standards for law enforcement.

- DOT (Department of Transportation) certifications for motorcycle helmets.

- ASTM and NOCSAE standards for sports helmets.

The Future of Helmet Testing Begins Today

As protective technology continues to evolve, helmet-testing equipment is keeping pace and advancing our understanding of safety. New materials, such as smart impact-absorbing foams and lightweight composites, require refined testing techniques to validate their effectiveness. Innovations in sensor technology and AI-driven analysis are expected to further enhance helmet testing accuracy.

Biokinetics remains committed to pushing for the next level of helmet safety, working alongside industry leaders to develop next-generation protective solutions.

For more information on our helmet testing capabilities, contact Biokinetics today.