Ballistic Manufacturers Need Due Diligence Measures They Can Trust

In the world of ballistic protection, “safety” is one of the most commonly used words, but also one of the least defined. As global threats evolve on a rapid scale, and manufacturers face the task of creating future-forward systems, the objective isn’t just protecting against known threats, it’s also ensuring protection is able to be measure, verified and validated. Due diligence has become a necessity and a key part of responsible engineering, meaning that it’s more imperative than ever to have regimented testing that enables credible performance and regulatory compliance.

With over 35 years of industry leading research, standards development, and biomechanical testing, the Biokinetics team knows that ballistic safety relies on more than pass-fail results. Safety depends on understanding the reality of injury mechanisms, matching solutions to real-world threats and ensuring products consistently perform to recognized standards. Simply put, as threats shift and new materials emerge, rigorous testing becomes the foundation for protecting human life.

Why the Definition of “Safe” Is Changing

Historically, ballistic performance centred on known, consistent threat levels. Today’s landscape is more complex. Across military, law enforcement, tactical and corrections environments, protective equipment must account for variables such as:

- Greater exposure to newer and different ammunition. While body armour is design to defeat common threats, the presence of additional ammunition types and even with over-matched threats, at increased engagement distances, are not addressed by test standards.

- Increasing use of less-lethal systems. Even non-lethal projectiles can cause severe injury without proper performance evaluation for injury risk. Manufacturers are now expected to demonstrate safety across a wider threat spectrum to purchasers and users alike.

- Regional variation in threat requirements. North American ballistic standards differ from those in the UK, EU, Australia, and other markets where blunt trauma and stab resistance can be prioritized differently. Differences in the threats can also result in different armour designs and performance so it is important to address actual threats encountered in their environment.

Ballistic testing is a quintessential part of answering these due diligence-based concerns effectively.

Why Due Diligence Is Essential for Manufacturers

Ballistic “due diligence” means taking a comprehensive, standards-aligned approach to product testing. It’s not enough for equipment to defeat a projectile in a controlled scenario; manufacturers must understand the injury implications behind test outcomes and be confident that the results accurately reflect real-world performance for the most reliable results.

This means that effective testing should be focused on:

1. Testing Against Recognized Standards

Whether aligning with NIJ, ASTM, NATO, or specialized agency standards, manufacturers must demonstrate that their products meet requirements using validated methodologies. Standards help create consistency, but the testing behind them must be executed with competency, precision and expertise to ensure the results are valid.

2. Evaluating Blunt Trauma, Backface Deformation & Human Injury Risk

Protection isn’t only about stopping penetration. Many life-threatening injuries can occur from energy transfer of the defeated bullet. Modern ballistic evaluation considers:

- Blunt impact severity in terms of energy, impulse and focal nature

- Tissue and skeletal injury potential

- Behind-armour trauma thresholds

Without factoring in these attributes, armour runs the risk of leaving the end user seriously injured, potentially even fatally so.

3. Assessing Performance Against Emerging Threats

New ammunition designs, materials, and velocities require adaptive testing strategies. Manufacturers need partners like Biokinetics, who bring the experience necessary to understand relevant threat trends, their implications with armour design and who actively contribute to standards development.

4. Ensuring Repeatability & Reliability

Consistency is critical when it comes to guaranteeing safety. True due diligence involves statistical reliability, quality control testing, and repeat assessments that confirm durability over time.

The Role of Biokinetics in Ballistic Certification and Development

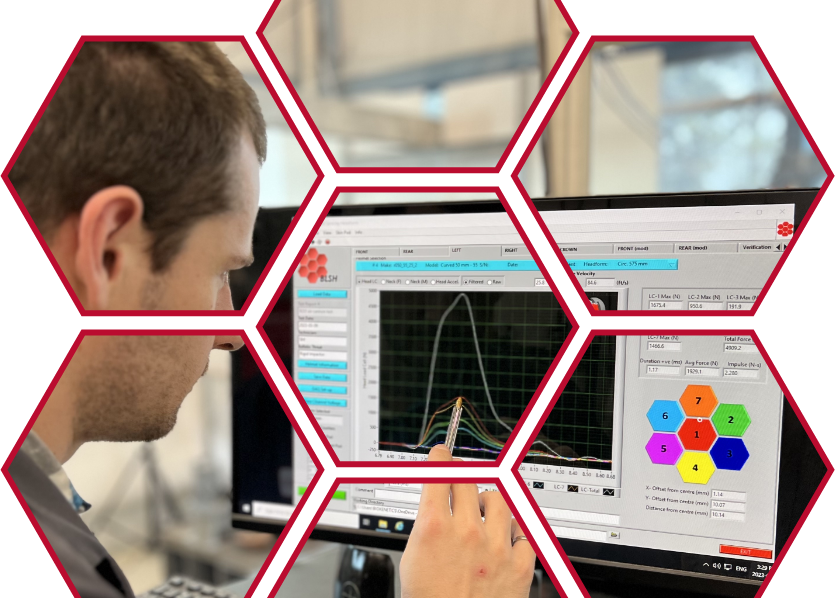

Biokinetics proudly supports manufacturers, researchers, and government agencies with independent ballistic testing and specialized consulting. Our multidisciplinary team has spent over three decades analyzing injury mechanisms and building the tools and test methods that help inform many of today’s accepted test methods.

We provide manufacturers with:

- Independent evaluation and validation. Our laboratories deliver unbiased testing aligned to the world’s most recognized ballistic standards.

- Custom and emerging threat assessments. When standards don’t yet address new risk categories, we design repeatable, scientifically grounded test methods.

- Insight into injury biomechanics. Our expertise goes beyond whether armour “stops” a threat—we assess what that impact means for the human body and how risks can be mitigated.

- And more.

Less-Lethal Isn’t “Less” Serious

With law enforcement and security sectors expanding their use of impact munitions and kinetic energy devices, manufacturers must ensure their systems limit injury while remaining effective. Biokinetics leads research in injury thresholds and test methodologies for less-lethal systems, helping agencies procure equipment that reduces risk to both officers and civilians.

Rigorous Ballistic Testing Builds Trust

When a manufacturer invests in scientific due diligence, the outcome is a credible performance claim backed by evidence. End-users, procurement groups, and regulators need confidence that equipment will perform as intended when lives are at stake.

Learn more about how Biokinetics assists with ballistic testing by contacting us today!