Protective sports equipment is essential for protecting athletes at all levels, from amateur to professional play. To perform as necessary, rigorous testing against a wide range of standards set by global leaders like NOCSAE, ASTM, and ISO is crucial.

At Biokinetics, we understand the importance of accurate performance testing to ensure equipment performs as intended when it matters most. With decades of leading experience, access to advanced testing facilities, and an innovative approach to safety assessment, Biokinetics is proud to offer solutions you can trust for product development, refinement, and more.

Below, we’ll explore the engineering principles and processes behind the effective testing of sports protective gear. Read on to learn more.

Engineering Protective Gear

Protective sports gear is designed to absorb and dissipate kinetic (impact) energy, reducing the risk of injury to the wearer. The key to protection is ensuring sports gear design effectively redirects or cushions forces to protect critical areas like the skull and brain. This means that the core objective of testing protective sports gear is to determine how well energy management is achieved by measuring factors like acceleration, force, and kinetic transfer.

At Biokinetics, we use precise tools and methodologies to simulate realistic conditions, ensuring the results apply to real-world scenarios for optimal dependability.

Realistic Testing Parameters

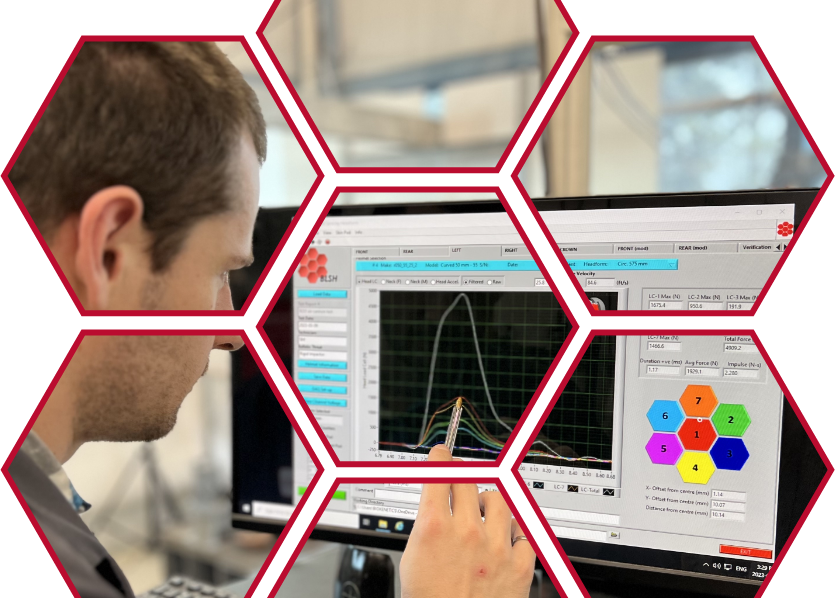

Valid tests must replicate practical conditions. For example, helmets must be tested to account for a fall or sudden impact’s energy to determine an accurate threshold and subsequent safety rating. Replication requires the use of appropriate models, tools, and resources to create realistic scenarios that can be translated into viable data. Biokinetics uses a wide range of equipment and methods to secure the best results, including ballistic load sensing headforms (BLSH), helmet drop carriages, blunt trauma thoracic rigs (BTTR), and more to capture accurate data on acceleration and force of impact to assess their potential for mitigating injuries.

It’s important to note that the energy levels selected for testing must be carefully evaluated; over-testing or simulating impacts that exceed real-world scenarios, for example, produces results that are irrelevant to actual use and may actually create protective products that diminishes safety at lower levels. On the other hand, under-testing can overlook critical failures that could happen in real-world applications and highlights the need for selecting energy levels and performance/injury thresholds that provide the greatest overall benefit.

Addressing Rotational Dynamics

Impacts to the body are typically characterized as being linear where padding materials are compressed. While straightforward to measure, the involvement of rotational dynamics in bodily injuries, the brain for example, also needs to be measured but present significant challenges especially when evaluating the natural twisting motions and glancing blows in sports like football and hockey. Rotationally induced injuries to the head stem from brain movement within the cranial vault, which stretches axons and causes neurological damage. Current regulators and standards groups are moving to find suitable test methods and performance thresholds to effectively address these risks. That is why, at Biokinetics, we employ advanced systems to measure both linear and rotational accelerations, enabling a comprehensive assessment of how protective gear performs under complex impact conditions. This dual approach ensures a more thorough understanding of injury risks.

Aligning with Standards and Best Practices

As we mentioned earlier, a wide range of established standards, such as ASTM and ISO protocols, are in place to define critical parameters, including test methods, energy levels, and pass/fail criteria for protective equipment. These standards specify numerous parameters, for example, the limit of linear and/or rotational kinematics that a helmet must provide to be considered effective.

At Biokinetics, our testing processes are designed to meet or exceed all relevant requirements for protective sports equipment. Our engineers ensure that each test aligns with the latest regulatory guidelines, producing reliable and relevant data.

Why Testing Matters

The importance of protective sports equipment cannot be overstated. Properly tested gear protects athletes from potentially catastrophic injuries, reduces manufacturers’ liability, and ensures compliance with safety standards. Rigorous testing also helps drive innovation by identifying areas where equipment can be improved to meet evolving safety demands, creating a safer foundation for all.

Benefit from Biokinetics’ Testing Expertise

Biokinetics brings five decades of experience to the field of protective gear testing, leveraging state-of-the-art laboratories to simulate realistic impact scenarios. We are proud to drive innovation and offer results that you can count on by utilizing an approach that combines rigorous adherence with compliance standards and emergent testing protocols that help address challenges such as rotational force impacts. Learn more by contacting our team today!