Whether a professional, amateur or recreational athlete, every sport contains some amount of injury risk. However, sudden impact to the head can lead to a variety of injuries, ranging from contusions and lacerations to concussions, skull fracture and severe traumatic brain injury. Even whiplash, often thought of as a neck injury, can involve concussion-like symptoms due to severe head rotation.

From professional leagues like the NFL to amateur competitions, the importance of reliable and effective protective equipment is paramount. At Biokinetics, we know how crucial it is to have vetted testing methods that determine the performance and effectiveness of protective equipment. As a leading Canadian innovator in the field of protective testing and analysis, our team brings over 45 years of expertise in head protection.

Below, we’ll explore a bit into head protection testing methods. Read on to learn more.

Energy Absorption

The purpose of protective headgear is to absorb impact energy. The premise is that the more energy that can be absorbed by the protective headgear, the less energy remains to inflict damage upon the structural and biological tissues of the athlete’s head. In sports, energy transfer to the head happens through a rapid change in its velocity – either the moving head is suddenly stopped, such as falling and striking the ground, or the head is struck by a moving object or another athlete. In both cases, this aggressive change in velocity introduces a risk of head injury. Protective headgear typically absorbs energy by way of deformation. The work done to compress the padding depletes some of the impact energy and allows the head to change velocity over a longer period of time, thus reducing the acceleration of the head. Since the force applied to the head is proportional to its acceleration, effective energy absorption ultimately decreases the force of impact. The overall objective is to reduce this impact force from one that is life-threatening to one that is survivable.

In practice, there are many factors that dictate the choice of padding materials in protective headgear and whether or not a structural shell should be added over top to spread the point of impact over a larger area, thus engaging more of the padding. If the padding materials are too stiff, then there will not be enough deformation, or ‘ride-down’ during the impact, causing the acceleration to be too high. Conversely, if the materials are too soft, then the head will ‘bottom-out’ in the padding, again causing a high acceleration.

Head Acceleration

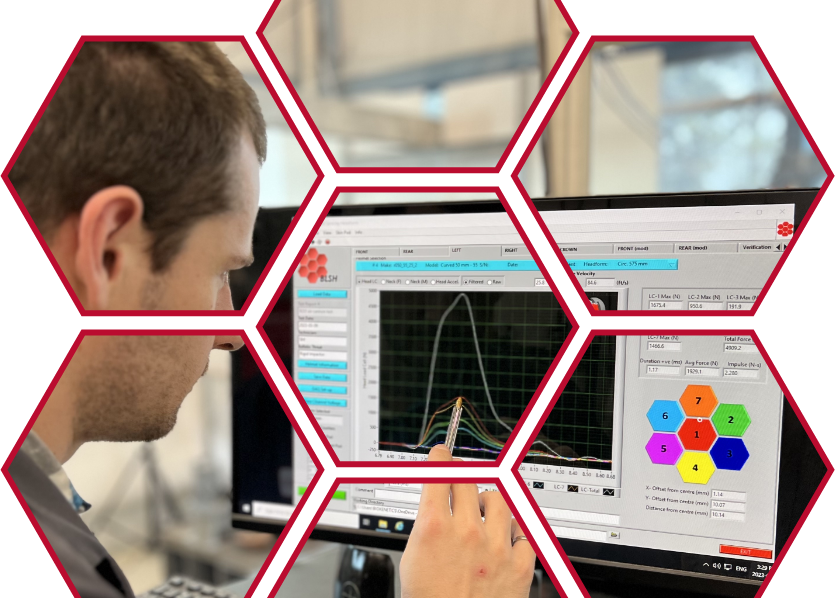

It is difficult to measure energy absorption directly, so instead, most protective headgears are tested by measuring the acceleration imparted to a test ‘headform’. The test headform is used to represent the athlete, and has the same general shape and mass properties of the human head. In the real world, there are a variety of impact scenarios possible, but in the laboratory, what is important is that the collision speed and impact energy imparted to the test headform are reasonably representative of real world collisions. Impact speed in the laboratory is accomplished using gravity and the test headform is dropped in guided freefall from a set height onto a rigid surface called the impact anvil. Depending on the sport, the impact anvil can be different shapes or materials to simulate real world impact surfaces. A single or trio of acceleration sensors called accelerometers are positioned within the test headform to measure the acceleration imparted to the headform during this impact.

A typical helmeted impact happens in less than 1/50th of a second, and requires data acquisition equipment to record the headform acceleration and display it using specialized testing software. Most often, the peak headform acceleration is converted to units of gravity, or G’s and a maximum headform G-level is dictated within a helmet test. The maximum G-level is typically associated within an accepted limit of human injury tolerance.

Test Standards

The above head acceleration test must be described in sufficient detail that it can be repeated in any laboratory in the world. But there are additional tests that a helmet must pass, such as the strength of the chin strap, resistance to penetration, prevention of roll-off and several more. Every test must be described by way of equipment and methodology as well as the pass/fail conditions. This collection of tests and other rules by which a helmet can be accepted for use by an athlete is called the helmet standard. Standards are living documents created by committees of experts having experience in sports, engineering, injury biomechanics and regulation. It is noteworthy that a standard must never be design restrictive and must be limited to how the helmet functions, not how it looks or what it is made from.

The Three R’s

Helmet standards demand the three R’s from their test labs: repeatability, reproducibility and reliability. Repeatability is a lab’s ability to keep all the testing details so precise that the same product can be tested multiple times and get the same result every time. Reproducibility is the ability for another lab to get the same results as the first lab. Reliability is the confidence that the instrumentation used to measure metrics like head acceleration and the systems that record that data, are accurate.

Compliance and Assurance

To accomplish reliability as described above, it is important to follow accepted calibration intervals for all laboratory electronics and other measurement devices, as well as to subscribe to an accepted quality model. Safety standards and regulations are constantly evolving as we gain a better understanding of different risks and factors that inform injury severity. Biokinetics ensures that all testing protocols adhere to the latest standards set forth by regulatory bodies and industry organizations and which are ingrained with our quality management practices.

Specialized Testing For Sports Safety with Biokinetics

Biokinetics is proud to offer industry-leading biomechanics knowledge, testing facilities and practices when it comes to assessing sports safety gear. Mitigating the risk of head injury and other bodily harm during sporting activity remains a dedicated area of expertise for our team, and we are pleased to offer comprehensive helmet testing services and more through our risk and performance analyses. Learn more about our helmet assessment and testing capabilities by contacting us today.