Helmet safety testing remains a vital concern when it comes to protecting both recreational and professional participants in organized sports, those commuting by bicycle or motorcycle, and individuals engaged in the many different activities that present a risk for head trauma. While the current methods and modelling behind standardized testing present a valuable way to evaluate and assess impact resistance, evolving technology and injury-related research necessitate the constant growth in our understanding of protective capabilities.

Below, we’ll take a closer look at a key variables informing the emergent future of helmet safety testing. Read on to learn more.

Crucial Emphasis on Rotational Impact Protection

A significant concern in the helmet safety world has become the issue of testing and addressing rotational impacts. Rotational force impact injuries have been linked to concussions, as well as traumatic brain injuries (TBI), and current methodology typically focuses primarily on linear impact. As our understanding of rotational force continues to expand, it is likely that the future of helmet safety testing will involve more comprehensive rotational impact studies. At present, researchers and regulatory bodies are working to develop standardized methods that replicate real-world rotational impacts, helping to gauge a helmet’s performance in reducing the risk of traumatic brain injuries.

Multi-Sport Versatility

Consumers have come to expect and look for helmets that can offer protection across a wide variety of activities in an effort to be efficient, as well as save money. This multi-purpose demand presents new challenges for regulators, who must now focus on assessing performance across multiple applications, and the simple reality is, traditional testing methods must shift to encompass the increased risk factors associated with multi-use units. As evaluation methods continue to evolve, it is likely that future testing will continue to adopt measures that allow for multi-modal evaluation and safety ratings to be better adapted to complex usage.

Customization and Fit

Scientists, engineers and safety regulators have all come to realize the increasing importance of manufacturing helmets that are able to be customized to fit an individual’s head as well as possible. Adjustable liners and personalized fit systems play a key role in performance, and as we continue to evolve our ability to design more advanced units, testing will need to be able to address the impact of customization when it comes to protecting users.

Technology, such as 3D scanning and 3D printing, will continue to play a significant role in creating customized helmets and testing protocols will likely evolve to incorporate the evaluation of technology-driven customization to ensure it enhances safety without compromising structural integrity.

Real-World Simulation

The efficacy of helmets in real-world scenarios is a forefront priority in helmet testing, and as our technological evaluation capabilities increase, we must continue to ensure that testing protocols accurately replicate actual conditions encountered by users, such as oblique impacts or side impacts in cycling accidents.

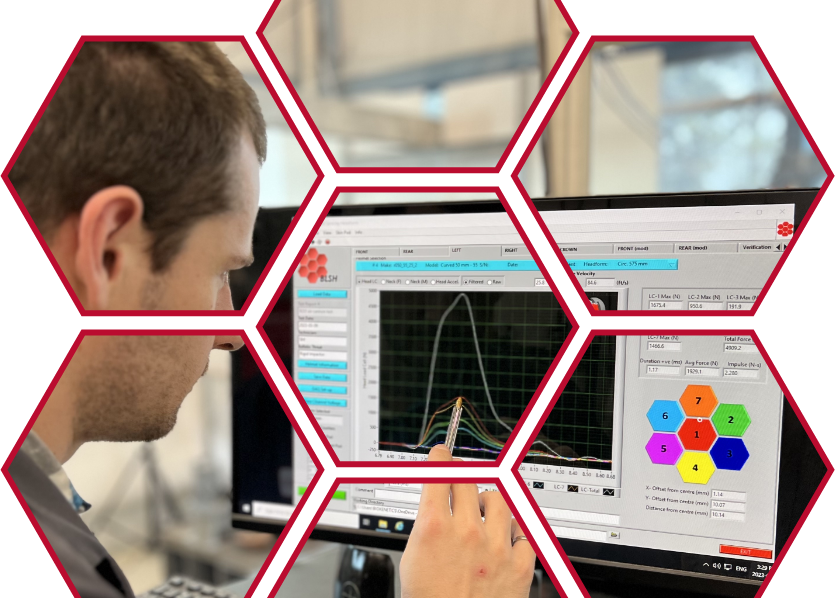

Advanced testing facilities and equipment, including computer simulations, high-speed cameras, and specialized impactors, are likely to play a more prominent role in helmet safety testing. Such tools help to enhance the realism of tests which ensures better performance and safety understanding for finalized products.

Helmet Safety Testing and Impact Injury Analysis with Biokinetics

Founded in 1975, Biokinetics is proud to have created a foundation of safety and knowledge when it comes to assessing equipment and establishing accurate safety metrics. Mitigating the risk of bodily harm during sporting activity remains a dedicated area of expertise for our team, and we are pleased to offer comprehensive helmet testing services through our risk and performance analyses.

Learn more about our helmet assessment testing capabilities by contacting us today.