Head, brain (TBI) and spinal cord injuries (SCI) remain some of the deadliest and most life-altering occurrences in the world of professional sports, as well as personal recreation. Helmets that adhere to current and evolving safety standards play an essential role in mitigating harm and allowing athletes of all levels to pursue their passion as safely as possible.

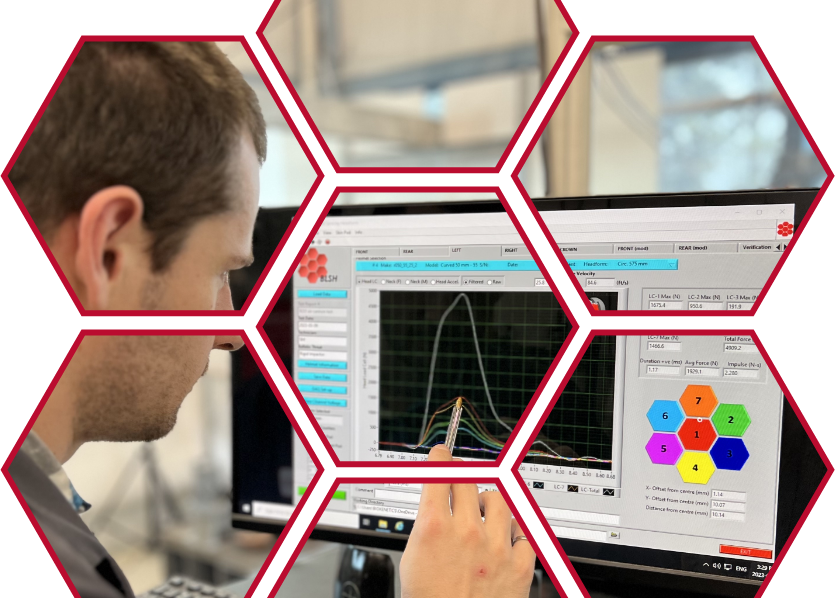

At Biokinetics, we understand just how important it is to conduct thorough product testing before market release to ensure helmets can uphold existing standards and allow for continued innovation for harm reduction.

Below, we’ll examine some of the core components examined during helmet safety testing. Read on to learn more.

Impact Protection

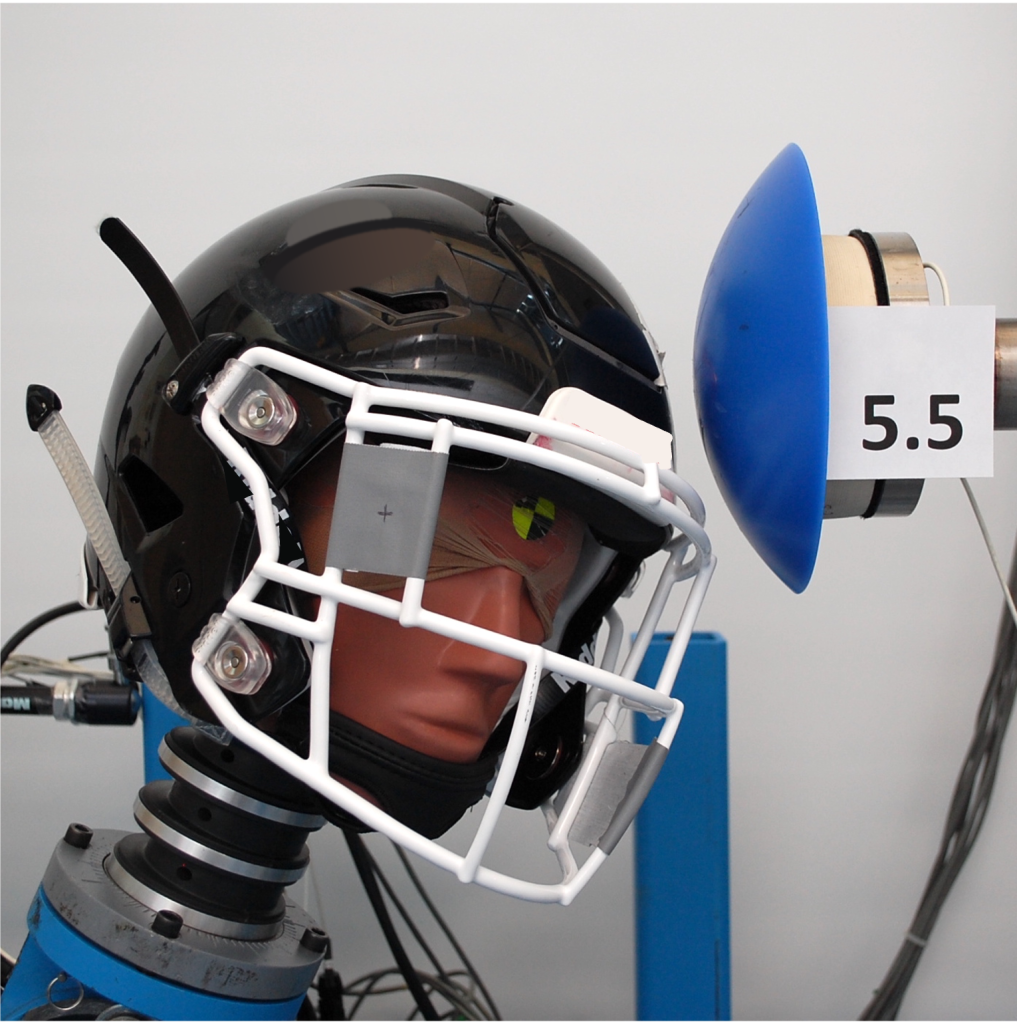

Helmets are ultimately designed to protect the head and neck against the dangers associated with blunt force trauma, which means that impact protection is a primary concern during development and testing. Helmets are created with a wide variety of factors in mind, and every element used in construction must balance aerodynamic performance alongside protective capabilities. Safety testing evaluates the outer shell’s ability to absorb and distribute impact forces effectively and the foam inner lining’s capacity to absorb force. Both elements must work together for optimal performance, and rigorous testing allows for a standardized understanding of how each unit performs under specific circumstances.

Fit and Retention System

As with any form of personal protection equipment, fit is key to ensuring helmets are able to perform as intended. Safety testing evaluates how units fit on different head shapes for stability and how well retention mechanisms (chin straps/buckles/etc) perform during impact to keep the helmet on the head. Dummy testing and laboratory tests allow for the testing of fit and retention mechanisms and help guarantee that users benefit from both once the product is viable for sale.

Helmet Weight

Helmet weight can be a lesser thought of risk factor that influences performance and user safety. When designing protective headgear, it’s essential to avoid units that are too heavy and can cause extenuating neck strain when used for prolonged periods of time. Evaluation of weight and load distribution allows manufacturers to accurately assess both elements and alter designs for increased efficiency and performance where necessary.

Ventilation

Ventilation is a core feature for comfort, but also plays an integral role in safety. Breathability helps to prevent users from overheating in hotter climates and, in doing so, helps to reduce the risks associated with elevated core temperatures, like reduced cognitive function and even loss of consciousness in extreme situations. Rigorous testing can help to assess how much heat is retained between the scalp and the inner layer of a helmet and how ventilation can best be integrated to suit comfort and safety needs.

Visibility and Design

Visibility and design go well beyond aesthetics when it comes to making helmets; they also play an integral role in protecting wearers. Coverage is a core consideration in helmet design, and visibility helps to alert others to the presence of the wearer to avoid impacts with a third party. Visibility also factors in the ability of the wearer to see their surroundings with ease, and with minimal hindrance from the helmet itself.

Building A Safer Path Forward

At Biokinetics, we know how important it is to ensure adequate and reliable helmet safety standards are met. For over 45 years, we’ve proudly partnered with industries across North America, including the professional sports world, to create a better understanding of risk mitigation through sports and equipment testing and blunt force assessment. Contact us today to learn how our services can help your team stay safe on the field.