Whether you’re on the field participating in a sport that has a high risk for significant impact like football or hockey, commuting by bicycle, or enjoying one of the many other recreational activities that warrant the use of a helmet, knowing that your protective equipment is up to standard is essential. Safety testing helps to ensure that helmets and other forms of personal protective equipment (PPE) perform as necessary when it matters most and protect the human body from serious harm. Head trauma can have permanent, life-altering, and even life-ending repercussions, and the right method of testing will help to define the impact threshold of specific designs and units.Below, we’ll take a closer look at the key differences between standardized and experimental testing for helmets and how they both play a key role in enhancing safety for wearers. Read on to learn more!

Standardized Testing

Standardized testing for helmets is a rigorous and systematic evaluation process designed to assess the safety and protective qualities of headgear in alignment with standardized industry regulations. While each industry and application will have different thresholds and aspects of evaluation, there several common factors that are routinely evaluated including impact resistance, shock absorption, strap integrity, and helmet stability. These tests use advanced technologies and specially designed equipment to simulate real-world scenarios, such as falls or collisions, which allow manufacturers and regulatory bodies to determine whether a helmet effectively safeguards the wearer’s head. The results of standardized helmet testing are crucial both for QC, but also to offer accountable reassurance that a specific helmet meets the highest safety standards and provides dependable protection.

Standardized testing forms the foundation for helmet safety evaluation. Standardized tests are established and widely accepted protocols developed by regulatory agencies and safety organizations. Their main purpose is to ensure that helmets meet minimum safety requirements, allowing them to be legally sold on the market. Essential aspects of standardized testing include:

Purpose and Context: Standardized tests are designed to evaluate helmets under controlled and repeatable conditions that create a reliable baseline for examination. Standards are crafted around the specific needs of the helmet in real-world scenarios, and tailored to provide accurate data.

Regulatory Compliance: Helmets must pass standardized tests to meet regulatory safety standards. These tests are typically mandatory and encompass parameters like impact resistance, retention system effectiveness, stability and peripheral vision.

Standardized tests also adhere to well-established procedures and parameters, such as specific drop heights, impact velocities, and headform specifications. These parameters are carefully chosen to replicate typical situations that users might encounter.

Data Interpretation: Standardized tests must yield quantitative data that can be compared across different helmet models and brands with a clearly defined pass/fail criteria that aligns directly with the objectives at hand.

Experimental Testing

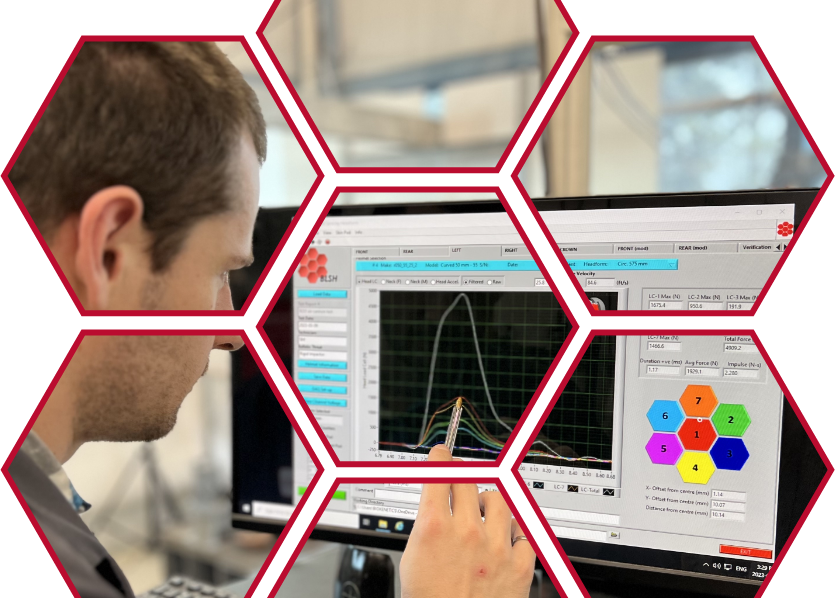

Experimental testing, in contrast, offers a more flexible and customized approach to assessing helmet safety. Experimental tests, as the title suggests, are more explorative in nature and examine helmet performance in specific scenarios that may not be fully covered or evaluated at all during standard tests.While this level of additional or supplementary testing may not be required for regulatory compliance, they contribute to a more comprehensive understanding about the holistic capabilities and boundaries of helmet performance. To achieve this goal, experimental testing may involve a wide range of parameters and scenarios including unconventional impact angles, different types of impacts (e.g., rotational impacts, high energy), or specific sports-related conditions. Testing can be further enhanced with advanced senors to measure linear and rotational head kinematics, neck loads, mandible forces and even details on the contact forces to help better understand the dynamics of the impact event and affect on injury potential.

The interpretation of experimental test data is often more context-specific and may require a deeper understanding of the specific test conditions in order to draw direct conclusions.

A Collaborative Effort For Safety

At Biokinetics, we know that both standardized and experimental testing play a vital role in assessing the protective capabilities of different kinds of headgear and PPE. While standardized tests provide reassurance that helmets meet minimum safety requirements for regulatory compliance, experimental tests drive innovation and research, scientists and engineers to explore new frontiers in helmet design and performance, ultimately pushing the boundaries of helmet safety.

Our team is proud to offer industry leading testing and experimental research services for sports equipment, including headgear as well as ballistics testing, accident recreation and assessment, and more.

Contact us today to learn more!